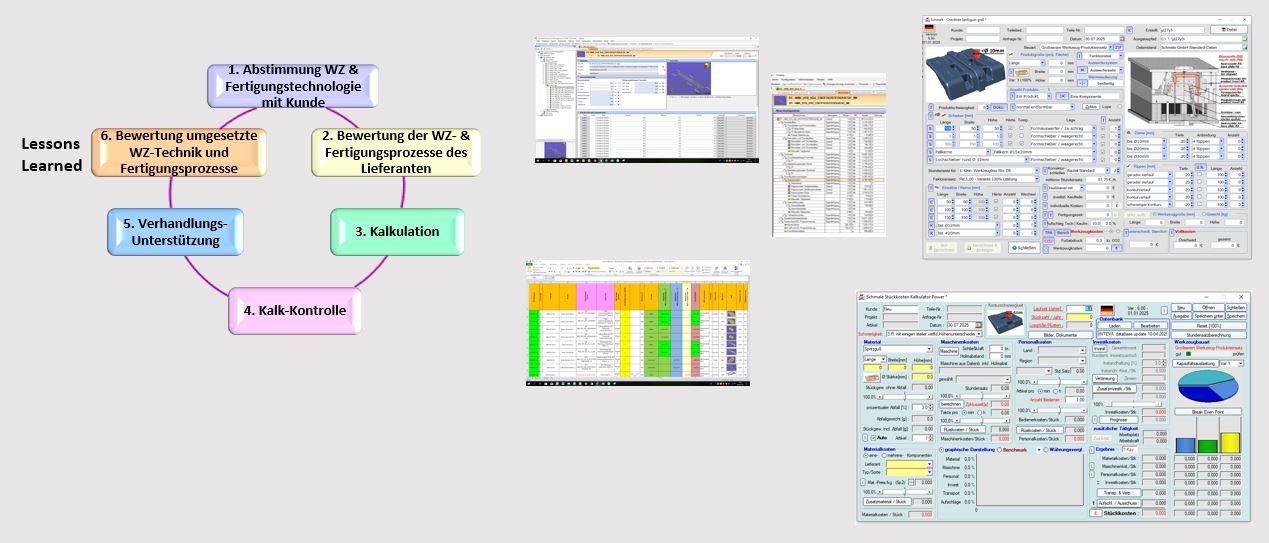

Calculation of Product and Tool Costs

Product and Tool Costing

Cost Engineering – Coordination of the technical requirements of the product with the manufacturing process, location and its conditions, as well as feasible tool concepts

Interim-Management

We provide you with interim specialists in short time for the following areas

- Project Manager Engineering

- Project Manager Industrialization

- Quality management

- Logistics planner

- Injection moulding application technology

Project management

Specialist for all production technologies for automotive interior parts (Machine and tool technology)

Injection moulding, bonding technology, laminating, thermoforming, edgefolding, plastic riveting

Innovation provider in the bonding and laminating technology

- Set up of Detailed specifications

- Offer evaluation

- Supplier selection

- Supplier coordination

- Commissioning, start-up coordination, Tool Tracking

Supplier Process Optimisation

Optimising processes and procedures

(technical optimisation – injection moulding, foaming, bonding, vacuum / press laminating, edge folding, as well as production processes and cost-saving measures)

- Machine and tool optimisation

- Scrap and rework optimisation

- Workplace design

- Time analysis

- Material flow management

- Organization and process optimization

- Personal support

- Implementation in the operations excellence (Synchronous Production System)

Examples:

- Cockpit foaming

- Door trim partial lamination

- SPS implementation leather insert

- Door trim manufacturing process implementation